Investigation of coatings and (boundary) layers

Non-destructive coating thickness measurement

- on plastic and anodised layers on non-magnetic base material

- on metallisations, e.g. copper layers on printed circuit boards

- Galvanic layers and lacquer layers on ferrous materials

Measurement methods

- magnetic inductive (DIN EN ISO 2178)

- magnetic (DIN EN ISO 2178) with eddy current (DIN EN ISO 2360)

- electrical resistance (4 peaks)

- X-ray absorption (XRF)

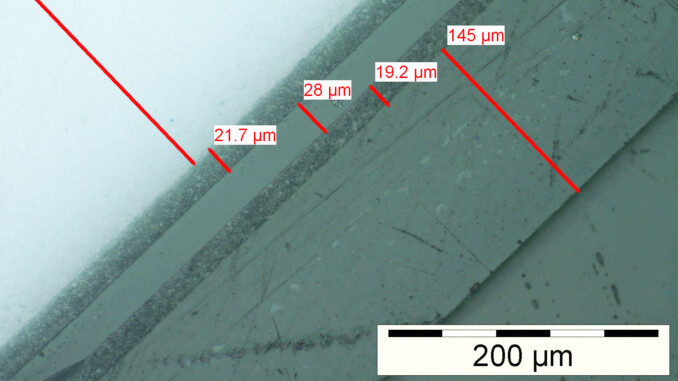

Destructive layer thickness measurement

- for case-hardened and nitrided coatings

- for galvanically grown (multiple) layers

- for metallisations

Measurement methods

- Light microscopy

- Scanning electron microscopy

Determination of layer composition and phase inventory

the chemical composition can be determined for most layers, the determination of the phase state requires crystallinity

Measurement methods

- Light microscopy / scanning electron microscopy

- X-ray spectrometry (XRF or EDX in SEM)

Hardness determination

- for case hardening and nitriding coatings for metallisations

Measurement methods

- Vickers hardness testing

Mapping of defects in a coating and at the interface

- in case of case-hardened, nitrided and anodised coatings (stress and hardening cracks, inclusions, etc.)

- for galvanic coatings and metallisations (delaminations)

- protective coatings (corrosion and reaction products, delamination, cracks)

- for welds (bonding defects, blowholes, cracks)

Mapping methods

- Mapping methods

- Light microscopy (HF, DF, POL, DIC)

- Scanning electron microscopy (HV, VP)