Infrastructure of the Institute

Our Offer

Would you like to have tests carried out in our laboratories or do you need a special measuring device? Just ask us.

The EMS Institute for the Development of Mechatronic Systems has laboratories with state-of-the-art measuring equipment and a considerable number of test benches. We are happy to use these for your service orders and development projects.

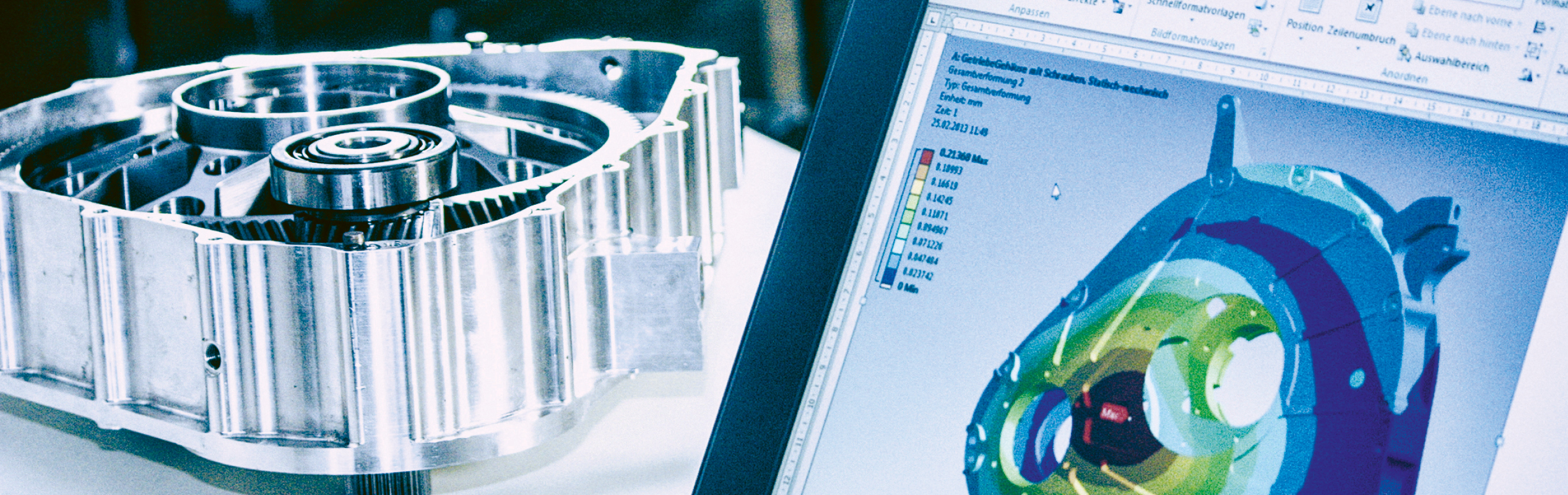

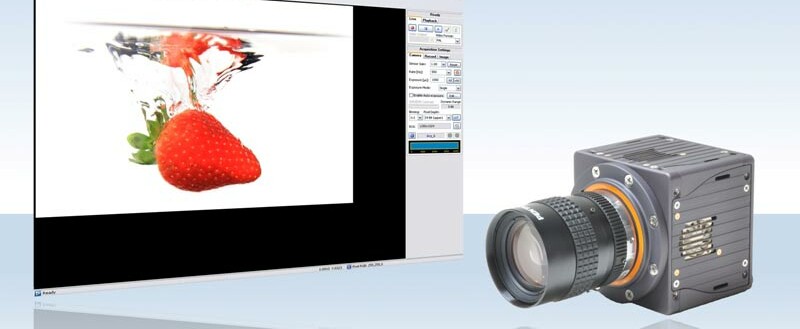

With an extensive test infrastructure, we are able to validate simulation results experimentally. For this purpose, the institute has laboratories with state-of-the-art measuring equipment and various test benches for R&D projects and service contracts. Hydraulic cylinders, electromagnetic shakers or piezo actuators can be used to apply specific dynamic excitations or loads. Modal analyses can be carried out on complex, difficult to access or small components using the laser scanning vibrometer. The robustness of products can be optimized with a drop test bench and a high-speed camera. The fatigue and fatigue strength of materials are determined using a bending circulation test bench. Force, displacement, acceleration and strain sensors or crack detectors are used to analyze specific problems.

Competent specialists take care of the required measurements, from setup to logging and evaluation. We are also fit for any reverse engineering and use state-of-the-art simulation software to optimize your results.

Specific measuring and testing equipment is set up for research projects and industrial quality assurance. For example, an axle test bench was set up with an industrial partner and battery test benches were designed, developed and set up for our research on batteries.

Would you like to have tests carried out in our laboratories or do you need a special measuring device? Just ask us.

Prof. Dr. Katrin LohanEMS Institut für Entwicklung Mechatronischer SystemeInstitutsleiterin, Prof. Robotik, Profilleiterin Mechatronics and Automation

+41 58 257 33 87katrin.lohan@ost.ch