Research project

Special machine for braces production - Fully automated aligner production

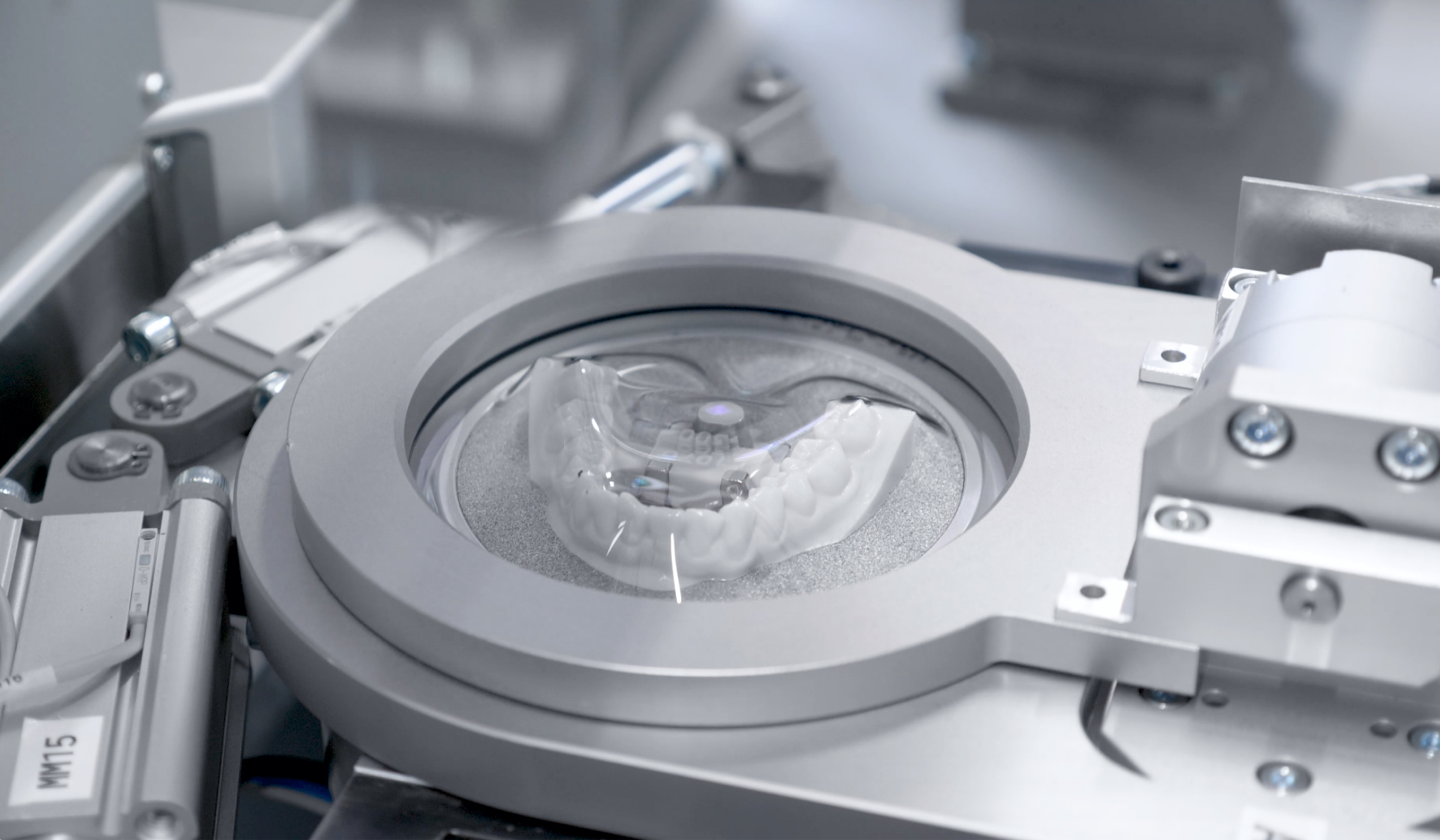

ILT Institute for Laboratory Automation and Mechatronics has developed a special machine for the production of braces in cooperation with bestsmile, the Swiss market leader for dental corrections. Through this digitalisation, bestsmile now produces in larger volumes and works even more efficiently.

Aligner

This is the name of the transparent braces that are manufactured at the production site in Winterthur. The aligners are custom-made braces for straightening teeth.

Initial situation

bestsmile, the manufacturer of transparent braces, has recorded a steady growth in orders since its foundation. The automation of the production steps was one of the goals in order to grow more digitally and efficiently. At the Winterthur production site, the process of aligner manufacture is fully automated - from 3D printing of the digitally captured dentures to deep-drawing the aligners.

Solution

In close cooperation with bestsmile, the ILT has developed a production cell, whereby a remarkable increase in throughput is achieved. In this development, the ILT once again demonstrates its interdisciplinary expertise in the fields of mechatronics, robotics, process development and Industry 4.0. Thanks to the high degree of digitalisation in production, customised dental splints are manufactured efficiently and automatically.

Partner:

bestsmile

Project manager

Prof. Dr. Agathe Koller

ILT Institut für Laborautomation und MechatronikInstitutsleiterin ILT, Studiengangleiterin Master of Science MSE, Professorin

+41 58 257 49 29agathe.koller@ost.ch