Research project

R&D at the HEPP plant

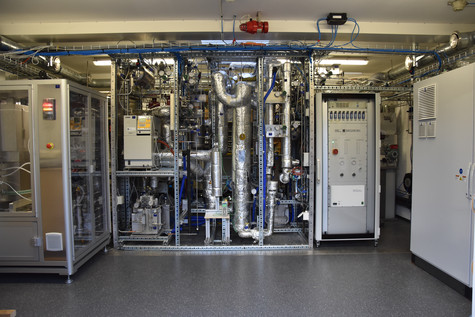

At the HEPP plant (High Efficiency Power-to-Methane Pilot), the IET Institute of Energy Technology is conducting research and development in the field of power-to-gas, power-to-X. In 2017, the power-to-gas team started this project with a lot of pioneering spirit. Today, almost four years after the first concept idea, the pioneering spirit is still present at our HEPP plant, only the pioneering romanticism has been partly caught up by everyday life.

Specifically, the HEPP plant is now more than two years old and maintenance and servicing work is due. Since the beginning of 2021, the plant has been systematically disassembled, worn parts replaced, measuring instruments sent in and recalibrated. We carry out this maintenance and servicing work on the one hand so that the HEPP is in perfect condition and we can continue to conduct research with it, and on the other hand so that we obtain reliable measured values. Of course, like any researcher, we live by the principle: If you measure, you measure crap. By checking the measuring equipment, we try to significantly reduce the proportional crap content.

The work is progressing well, despite certain delays in delivery of sent-in equipment, so that the HEPP facility can be used for research again in March.

Anecdote:

The research dock has been built (rebuilt/expanded) very compactly, this has meant that we have not been able to get everywhere with an open-end wrench. One of the maintenance activities was to retighten the seat packing on our ball valves. To do this, we had to cut various open-end wrenches in half.... Comment from our workshop: "Are you sure you want to destroy the beautiful tool?".

Conclusion: the open-end wrenches are cut in half and the seat packings are tightened.

Before the service and maintenance work, we were able to achieve the first small successes in the area of Sorption Enhanced Methanation (SEM). SEM is also a catalytic methanation process using a special catalyst supported on a zeolite. Conventional methanation catalysts usually have pure alumina as a support material. Thanks to the properties of zeolite, with this special SEM catalyst, pure and dry methane is obtained at the reactor outlet.

The SEM technology has already been extensively tested in the UMTEC laboratories, but the integration of this technology into the HEPP plant was not trivial. The challenge was to scale the gas flows from "micro to mini." The solution word for this challenge was bypass. We installed bypasses at various points in the HEPP plant. This allowed us to integrate the UMTEC SEM reactor with micro gas flows into the HEPP plant with mini gas flows. With this step, we are able to test an operating concept for a power-to-gas plant with SEM catalyst, which was not possible in the laboratory scale. The test series, which is planned for March/April, will provide the design basis for SEM reactor system, which has a methane production capacity of 0.5 - 1 Nm³/h. This corresponds to a 200 to 400 times higher methane production capacity. This represents a 200 to 400-fold scale-up of methane production capacity from laboratory scale.

Anecdote:

The "beer blanket calculation" is a pragmatic tool which is very popular at applied science colleges. With this tool, however, watch out for the Popeye error. As with spinach, the decimal place is also relevant when converting units, e.g. that "ml/min" does not suddenly become "liters/min".

Conclusion: Apply the four-eyes principle also for "beer blanket calculation".

One of the central goals that the IET Institute of Energy Technology is pursuing with the HEPP plant is to increase the efficiency of the entire power-to-gas plant. This is to be achieved by coupling the reactor waste heat with a high-temperature electrolysis (SOEC: solid oxide electrolyzer cell). A first intermediate goal could already be achieved here, a first efficiency analysis of the HEPP plant with the PEM electrolysis. In order to achieve the main goal, the IET Power-to-Gas team is working closely with EPFL in Sion. The teams are working on the multi-stage commissioning of the high-temperature electrolysis to ensure that the coupling of the methanation and the SOEC runs as smoothly as possible.

High Efficiency Power-to-Methane Pilot - HEPP

The HEPP (High Efficiency Power-to-Gas Pilot) project was conducted from 2017 to 2020 and implemented by a sponsorship of research funding and industry. The research results flow into the European Union's Horizon 2020 research framework program in the Pentagon project, which involves a total of ten institutions from academic research and industry from five European countries.

High efficiency with technical innovations

Using technical innovations, experts at the IET Institute of Energy Technology aim to increase the technology maturity of power-to-methane technology and demonstrate it on a small scale in a real-world environment. The innovations in this project relate to efficiency, so that the economic viability of the technology is increased and the environmental impact of the methane produced is reduced. Industrially relevant questions will be answered so that a transfer of the technology to a large-scale plant with an efficiency of 70% will be possible.

The core element in the HEPP project is a 10 kW demonstration plant, which is being built in Rapperswil. The concept of the plant includes a high-temperature electrolysis and an integrated heat management. In addition, the project integrates innovative technologies developed in Switzerland for the first time and investigates system behavior.

"The demonstration plant was inaugurated in the fall of 2018 and has since been shown to 1,200 visitors in guided tours. Current projects will run until mid-2021, and the IET's power-to-X activities will expand to other topics, with additional projects being developed at the facility. Please send requests for guided tours to the following email address: besuch-ptx(at)ost.ch

Team:

Luca Schmidlin

IET Institut für EnergietechnikWissenschaftlicher Mitarbeiter

+41 58 257 43 35luca.schmidlin@ost.ch

Christoph Steiner

IET Institut für EnergietechnikWissenschaftlicher Mitarbeiter

+41 58 257 43 49christoph.steiner@ost.ch