Thermodynamics laboratory

Climatic chambers

The thermal energy systems division has three climatic chambers.

The two large climatic chambers can be used separately or in combination.

As separate units, experimental setups and test stands can be tested under different climatic conditions.

As a composite, the climatic chambers can act as a heat source and heat sink for heat pumps, for example.

The third, smallest climatic chamber, also called climatic chamber, can be used very flexibly.

This was developed and assembled by the Institute for Energy Systems.

Soundproof climatic chamber

Sound power level measurements carried out in our laboratory and in the field according to the international standards EN ISO 9614-1 and 9614-2.

Sound pressure measurements in anechoic sound room and in the field

Frequency band analyzes from 10 to 20,000 Hz using sound pressure or sound intensity to determine the interference frequencies of a machine

Software for the determination of harmonic harmonics of a machine to minimize structure-borne noise transmission in the system

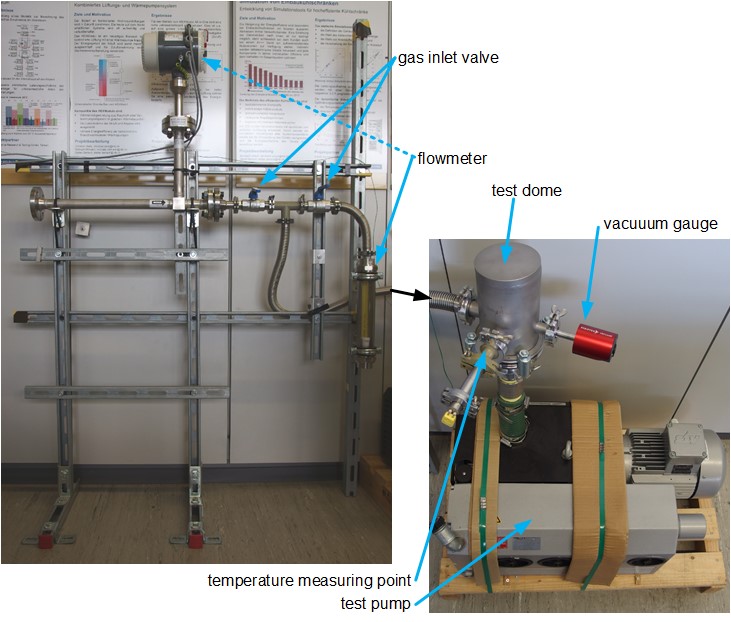

Vacuum pump test bench

A vacuum pump is characterized, among other things, by its characteristic curve, which again shows the relationship between the suction pressure and the suction capacity.

In order to determine such vacuum pump characteristics, a test stand was set up with which vacuum pumps with nominal pumping speeds between approx. 20 and 120 m3 / h can be measured.

With the test bench, measurements can be made using the procedure in accordance with ISO 21360-1, which is described under "5.1 Volume flow rate measurement by the throughput method".

Several sensors with different measuring ranges are used to measure the pressure and the volume flow.

Compressor test bench

With the compressor test bench, the performance and efficiency characteristics of refrigerant compressors can be determined.

To do this, the desired pressure and temperature conditions are set and the test stand records the mass flow and electrical power consumption of the compressor under these conditions.

The refrigerant mass flow is measured directly with two mass flow sensors based on the Coriolis principle. All important measured values are recorded twice redundantly and the temperature sensors are positioned within the refrigerant lines.

Compressors on the scale of heating pumps for single-family houses can be tested.

Thermal camera

FLIR T650sc

The institute has a thermographic camera with a resolution of 640 x 480 pixels. This is a very helpful tool both in power electronics development and in the development and commissioning of thermal systems.

- IR resolution: 640 × 480

- Integrated daylight camera

- Termpartur calibrated video recordings with 30fps

- MSX® image enhancement technology

Data acquisition

Measurement systems from National Instruments are mainly used for data acquisition.

The institute's staff develop a separate control program for each new test stand using the LabView software from National Instruments. This program not only controls the test stands directly from the computer, but also records and evaluates the measured values from the sensors.

With the associated ComapctRio hardware, a wide variety of sensors, such as temperature sensors, flow sensors, power sensors, etc. can be recorded simultaneously.

Inventory:

- CompactRio (cRio)

- NI measurement cards of different types suitable for CompactRio (cRio)

Measuring instruments

With many different sensors, the institute is able to record different measured values. The sensors can be used for a wide variety of fluids in different phases (liquid, gaseous). The following sensors can be used:

- Volume flow sensors (liquid, gaseous)

- Coriolis sensors

- Temperature sensors

- Enthalpy and humidity sensors

- Pressure sensors (absolute, difference)

In addition to the sensors and measurements at the institute, the institute can use various data loggers to analyze and measure systems on site and during operation.

Contact

Prof. Stefan Bertsch, Ph.D.Fachabteilung SystemtechnikProfessor, Fachabteilungsleiter SYS, Institutsleiter IES

+41 58 257 34 69stefan.bertsch@ost.ch

Did you know that sharing the work with us can reduce the costs of your project by up to 50%?